Project Information

| Construction Date : In Progress, (August 2017) |

| Location : Ontario, Canada |

| Category : Parts Washer |

| Firm : Briggs Manufacturing |

Project Details

“Design and Manufacture of Parts washer with Deburr.”

Our client, a world class manufacturer of utility engine blocks, contracted Wuulf Machine to design and build a cleaning and deburring system for their 200cccc line.

More Project Details

The upstream machining processes included milling, grinding, drilling boring and honing. Our design process always involves a deep understanding of contaminants and the generation of these contaminants.

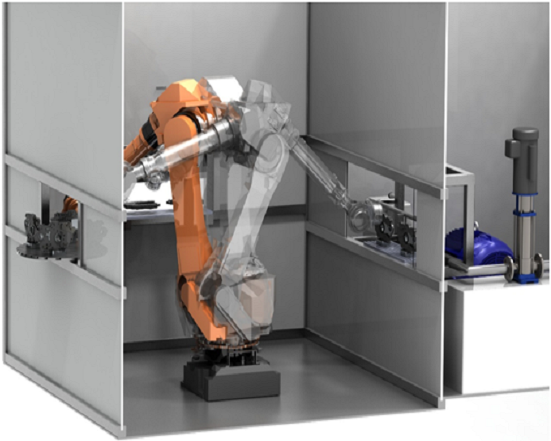

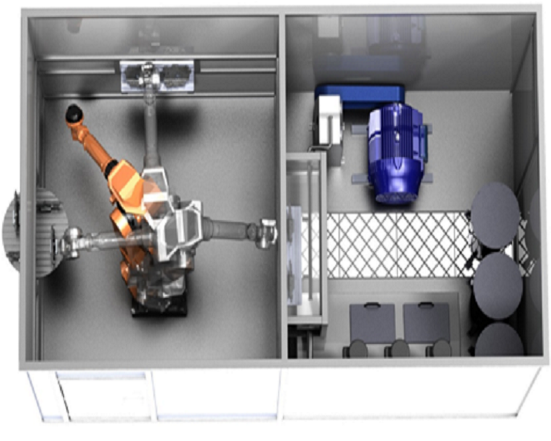

The turnings from a drilling process is different from the ones generated from a back-boring operation. Once all of the possible foreign materials are identified we conducted a PFMEA and listed countermeasures for each. Due to the space limitations within the plant we designed for a very small foot-print, with an ABB robot doing the material handling. The blocks are loaded on to a small two position rotary table. The table indexes and presents to the Robot. The robot is equip with double end effectors in the interest of cycle time.

The robot then moves the part through the various stations, deburr, high pressure wash, rinse, and drying. All the while the robot remains dry and contained, even though the Robot is IP64 rated.

The pump house and ancillary equipment is housed in a separate area which makes easy access for maintenance. Every station was thoughtfully designed for function, ease of maintenance, reliability and reparability.

We ensured that the whole system was designed for optimum energy efficiency. For example, dump valves were used to relieve the pressure on the pump in between cycles; we insulated the coolant tanks as well as the filter bag housings

Our customer was extremely satisfied with results and we are currently working on another special purpose machine.