PARTS WASHING

Wuulf Machine will work with you to fully understand your needs, our experience with various process, upstream and downstream of your intended parts cleaning application gives us an edge on the competition. We pay close attention to the incoming contaminants, be it water or oil based coolants, oils, cuttings from raw machined parts produced by milling, turning, grinding, laser and conventional welding, EDM, casting and so on. Equally important are the post wash operations that follows, be it manual assembly, leak or other types of testing.

The depth and breath of our engineering expertise when it comes to the cleaning of traditional and exotic materials and components, with various part geometries, formed by machining, hot or cold rolling, punch pressing, welding, heat treatments pressing and so on, is unsurpassed. Our experience with various deburring techniques and their application with respect to part geometry and material is second to none.

We can upgrade, modify and re-engineer older and obsolete washers to meet alternative application specifications, including custom built machines which can be tailored to fit an existing floor plan.

- High pressure washing

- High pressure deburring

- Low pressure washers

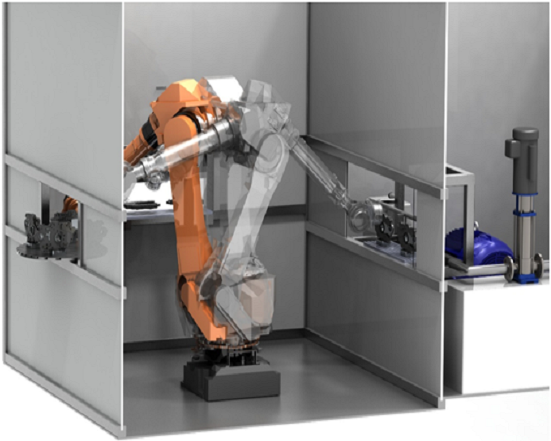

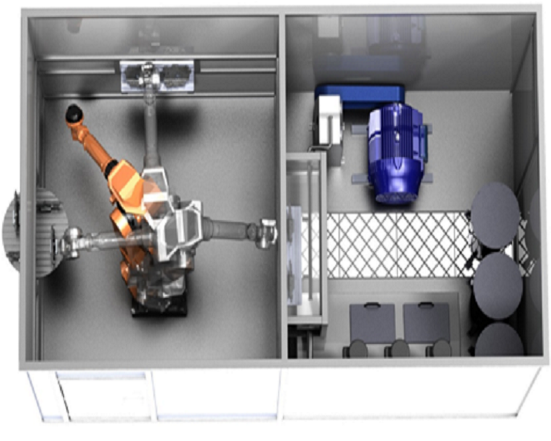

- Robot washers

- Tunnel type washers

- Rotary table index washers

- Immersion type washers

- Ultrasonic washers

- Combination ultrasonic and spray washers

- Wash results to ISO 16232 and VDA 19